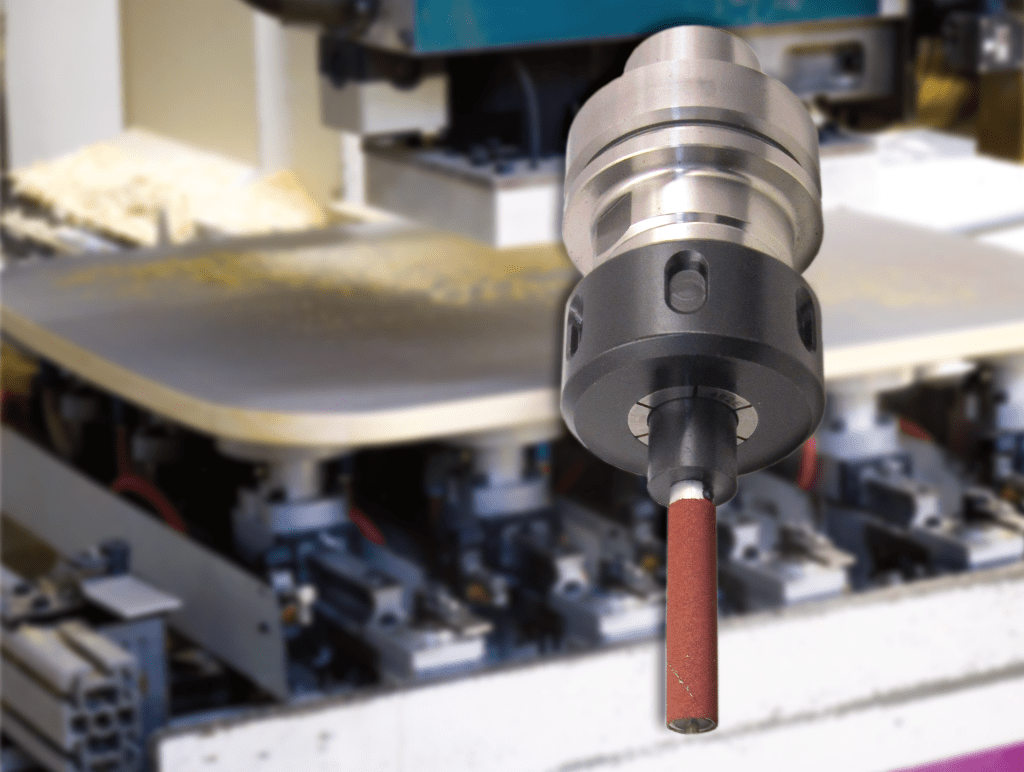

In addition to the conventional mounted sanding points in our range, we are now introducing the compact mounted point into our portfolio. The high-quality ARMINIUS mounted sanding point from our range of craft & industrial products is designed for long-lasting use on stationary machines.

ARMINIUS mounted sanding points are used for internal cylindrical sanding of all milled out recesses. The cylindrical point consists of a robust base body on which the interchangeable abrasive sleeves are used. With the smallest diameter starting from 10 mm, the product allows for effortless machining of internal curvatures. Its machining height of up to 130 mm enables a flawless sanding result through oscillating movement. With the optimal speed of between 4 to 8 m/min, users achieve the best sanding performance without any rework.

Fine sanding is already achieved in the first pass with the ARMINIUS mounted point. Precise wood removal is ensured by the robust construction of the sanding point as well as its reliable runout accuracy. Thus, the user only needs to schedule only one machining pass. The choice of grit for the abrasive sleeve depends on the user’s desired final grit. This is why we manufacture the sanding sleeves in all grits.

ARMINIUS mounted sanding point are suitable for all kinds of wood materials. To ensure a long service life for each user, we deliberately avoid paper-based sanding materials.

For processing solid wood, MDF, and HDF, the sanding sleeves are made of high-quality sanding cloth. Traditionally, as a marking, the sanding sleeves are red.

For processing multiplex and construction beech, we recommend our green sanding sleeves. These contain harder corundum, which is usually not needed for solid wood, but has become more and more common for sanding of multiplex and construction beech. Both sanding materials are the same price. For best results, we wish to offer our customers individual choice.

To achieve a uniform color result on the workpiece, we generally recommend choosing a uniform grit for both the wood surface and the wood edge when selecting the grit of the sanding sleeves.

For recesses in solid wood, the face of the wood grain, among other areas, needs to be sanded. Here we recommend a grit one degree finer than the one used for the surface. The same applies to the processing of MDF. Depending on the thickness of the workpiece and the composition of the medium-density fiber layer inside the fiberboard, an even finer grit may be advisable.

ARMINIUS mounted sanding points are equipped with a cylindrical shaft. Customers individually select the suitable shafts for their machines. The cylindrical shaft is produced entirely according to customers’ requirements, at identical prices.

In addition, a CNC holder is included with each mounted sanding point. The HSK-63F holder is permanently on stock. However, delivery is also possible for all other CNC holders.

For the immediate use we always deliver our ARMINIUS mounted sanding points with a tool measurement. Therefore, we recommend ordering the sanding point with a suitable holder for CNC machining. The supplied tool measurement ensures immediate usability on your machine.

You can find more information about our conventional sanding points and ornamental grooves for woodworking under the following link:

https://www.arminius.de/en/products/mounted-sanding-points-ornamental-grooves/

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationWhether in writing or by phone: We are always available for you!

ARMINIUS Schleifmittel GmbH

Paderborner Str. 65

D-32760 Detmold, Germany

ARMINIUS Schleifmittel GmbH

Paderborner Str. 65

D-32760 Detmold, Germany

ARMINIUS Schleifmittel GmbH

Paderborner Str. 65

D-32760 Detmold, Germany

Arminius Tooling Inc.

P.O. Box 68

FORESTON, MN 56330, USA

ARMINIUS Schleifmittel GmbH

Paderborner Str. 65

D-32760 Detmold, Germany

ARMINIUS Schleifmittel GmbH

Paderborner Str. 65

D-32760 Detmold, Germany

Arminius Tooling Inc.

P.O. Box 68

FORESTON, MN 56330, USA

ARMINIUS Schleifmittel GmbH

Paderborner Str. 65

D-32760 Detmold, Germany

You are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information