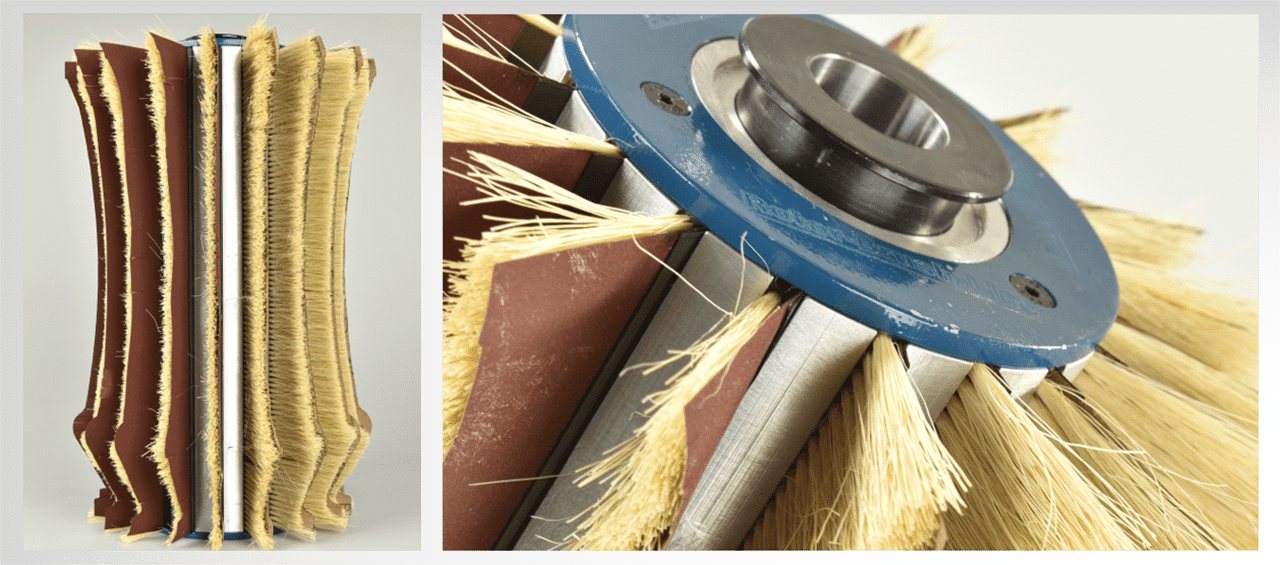

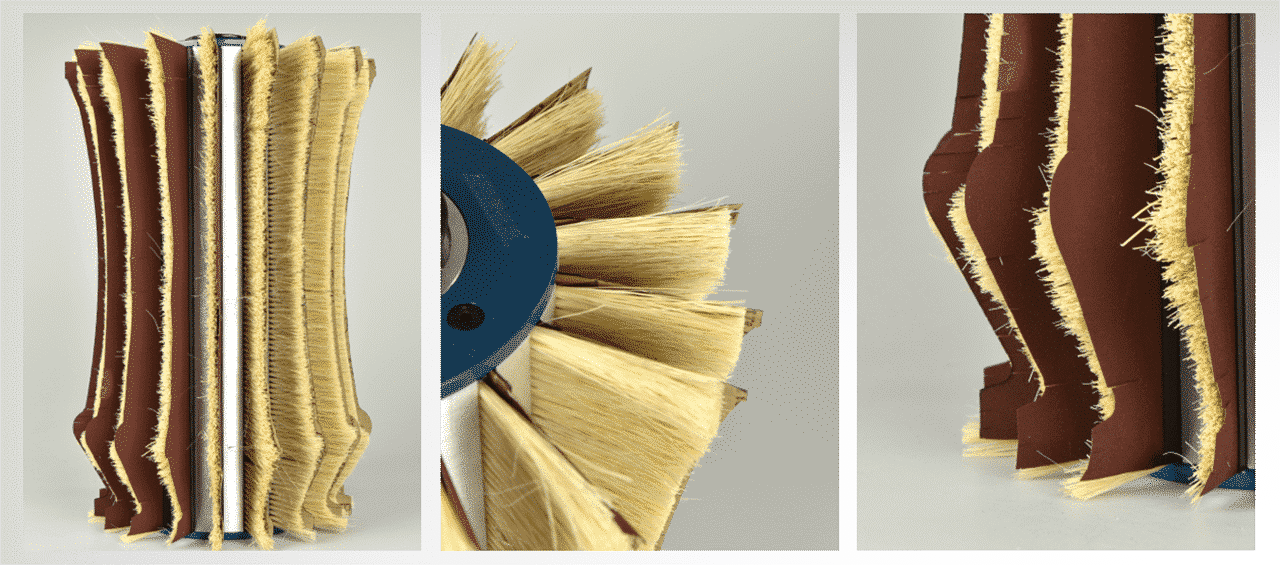

ARMINIUS fertigt hochwertige Bürsten zum Strukturieren von Holz und Furnierholz für den Einsatz auf stationären Maschinen. Um das fertige Strukturergebnis bereits mit dem ersten Maschinendurchlauf abzuschließen, hat ARMINIUS ein Bürstensystem mit Wechselelementen konzipiert. Die einfache und schnelle Kombination der einzelnen Borsten spart dem Nutzer viel Zeit und lässt Spielraum für spontane Design- und Projektänderungen.

Die Borsten aus Messing und Stahldraht bestücken für besonders aggressive Herausarbeitung im Hartholzbereich. Die Kunststoffborsten ist zum Strukturieren von Weichholz bestens geeignet. Durch das Einmischen von Kunststoffborsten werden hervortretende Holzfasern direkt entfernt. Ideal für die Bearbeitung von Eiche und Buche.

So einzigartig wie jedes Werkstück, so einzigartig ist auch die natürliche Holzmaserung. Beim Bürsten einer Holzoberfläche werden die Weichholzanteile heraus gebürstet. Hier ist es wichtig entlang der Holzmaserung zu bürsten. Die Strukturoberfläche erhöht den natürlichen Wohlfühlfaktor und ist deshalb so beliebt wie kaum ein anderes Gestaltungsmerkmal im Innen- und Außenbereich.

Der Einsatz der ARMINIUS Bürsten hat sich auf CNC Maschinen etabliert. Der Anwender bürstet seine Holzoberflächen in nur einer Aufspannung sehr effizient und zeitsparend. Die Wahl der Borsten wird meist aus einer Mischung der Borsten aus Messing und Kunststoffborste gewählt. So erzielen unsere Anwender nach nur einem Durchlauf die gewünschte Strukturoberfläche.

Die Bürsten zum Strukturieren werden nach Kundenwunsch und Maschinenbeschaffenheit konstruiert. Hierbei werden selbst innenliegende Radien gebürstet, welches größtenteils in der Türherstellung und Möbelfertigung großen Anklang findet.

Die ARMINIUS Bürste bürstet die Oberfläche mit einer passgenauen Strukturtiefe, selbst bei leichten Furnieren. Im Objekt- und Innenausbau werden nicht nur unterschiedliche Komponenten zusammengefügt, mit einer strukturierten Holzoberfläche bilden sie zudem einen besonderen Blickfang.

Ob bereits bestehende Schleifmaschinen oder Durchlaufmaschinen, die ARMINIUS Bürsten sind auf allen stationären Maschinen und Maschinenanlagen einsetzbar. Teilen Sie uns Ihre Maschine mit und wir fertigen die passende Bürste für Sie. Unsere Walzenbürste zum Strukturieren auf Tischfräsen sind bis zu einer Drehzahl von 1500 U/min bestens geeignet. Sollte Ihre Tischfräse mit einer höheren Drehzahl arbeiten, so empfehlen wir hier unsere ARMINIUS HighSpeed Bürste.

Die Besonderheit der ARMINIUS Bürste ist der flexible Wechsel der Strukturelemente aus Stahldraht, Messing und Kunststoffborste. Die Bürste besteht aus einem festen Grundkörper und austauschbaren Einsätzen. Damit kann der Anwender auf jedes Projekt mit nur einem Bürsten-Grundkörper eingehen. Je nach Holzart und Wechselbestückung der Bürsteneinsätze lassen sich eine Vielzahl von Strukturvariationen verwirklichen.

Die offene Auslegung der ARMINIUS Bürste gewährleistet eine nahezu restlose Span- und Staubabsaugung am Werkstück und an der Bürste. Der selbstkühlende Effekt ergibt sich aus der Kühlrippen-Bauweise der einzeln angeordneten Borsten. Selbst im Dauerbetrieb weist die Bürste keine Wärmentwicklung an der Motorspindel auf. Das schont nicht nur die Maschine, sondern steigert auch die Standzeit der Borsten, die sich durch die kühlende Funktion fast verdoppelt.

Durch den zweiteiligen Aufbau wird der Verbrauch von Strukturelementen auf ein Minimum reduziert. Das ressourcenschonende Bürstensystem von ARMINIUS reduziert nicht nur die Lagerkosten, sondern erzielt auch eine Ersparnis bei der Werkzeugbeschaffung. Wir liefert auf Kundenwunsch und verzichtet bewusst auf vorbestimmte Verpackungsgrößen.

Hinzu kommt für unsere Anwender noch ein weiteres, unschlagbares Feature: der ARMINIUS Bürstgrundkörper ist sowohl mit Bürstelementen zum Strukturieren als auch mit Lamellen zum Schleifen nutzbar. So ermöglicht derselbe Grundkörper zwei verschiedene Anwendungen und ist zudem durch seine massive Bauweise über Jahrzehnte einsetzbar. ARMINIUS erweitert kontinuierlich das Sortiment an Strukturborsten, um sämtliche Anforderungen unserer Anwender zu bedienen.

Für die CNC-Bearbeitung oder den Einsatz in Maschinenanlagen fertigen wir unsere Bürsten mit individuellen Durchmessern und Nutzlängen. Teilen Sie uns Ihre Maschinenanforderung mit und wir konzipieren die Bürste ganz nach Ihrem Bedarf und Anforderung. Unsere Bürsten sind für dauerhafte Belastungen ausgelegt und werden daher von unseren Kunden schon seit Jahrzehnten eingesetzt.

DI (mm) | H (mm) | B (mm) | Aufnahme | Identnr | |

|---|---|---|---|---|---|

50 – 250 | 20 – 3.000 | 8 – 120 | HSK-63F oder zylindrischer Schaft | WB-Zylinder |

Legende:

DI = Innendurchmesser / H = Nutzlänge / B = Bohrung

Die gesuchten Abmessungen werden nicht aufgeführt?

Dann wenden Sie sich direkt an unsere Anwendungsberatung!

Unsere Winkelbürsten werden nach Ihrem speziellen Bearbeitungswinkel individuell gefertigt. Der Grundkörper der Walzenbürste ist sowohl mit Borsten zum Strukturieren der Holzkante einsetzbar, als auch im Nachgang mit Schleiflamellen zum Schleifen der Holzwerkstücke bei spontanen Projektänderungen.

Sie möchten eine hohe Holzkante mit einer zusätzlichen Fase oder Radius strukturieren, hier besteht jederzeit die Möglichkeit die Winkelbürste mit einer Walzenbürste aufzustocken.

Teilen Sie uns Ihren Bearbeitungswinkel und der gewünschten Höhe der Holzkante mit, wir fertigen Ihnen die Bürste zum Strukturieren von Holz und Furnieroberflächen nach Ihren Bedarf und ohne zusätzliche Kosten.

D (mm) | H (mm) | W (mm) | B (mm) | Aufnahme | Identnr. | |

|---|---|---|---|---|---|---|

80 – 300 | 20 – 125 | 10° – 80° | 8 – 110 | HSK-63F oder zylindrischer Schaft | WB-Winkel |

Legende:

D = Durchmesser / H = Nutzlänge / W = Winkel / B = Bohrung

Die gesuchten Abmessungen werden nicht aufgeführt?

Dann wenden Sie sich direkt an unsere Anwendungsberatung!

ARMINIUS Stirnbürsten eignen sich für den Einsatz in der CNC-Bearbeitung und auf Maschinenanlagen.

D Durchmesser (mm) | Bohrungsdurchmesser (mm) | Aufnahme | Identnr. | |

|---|---|---|---|---|

80 – 300 | 8 – 50 | HSK-63F oder zylindrischer Schaft | WB-Stirn |

Legende:

D = Durchmesser / H = Nutzlänge

Die gesuchten Abmessungen werden nicht aufgeführt?

Dann wenden Sie sich direkt an unsere Anwendungsberatung!

Sie sehen gerade einen Platzhalterinhalt von Vimeo. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenSie sehen gerade einen Platzhalterinhalt von YouTube. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenSie müssen den Inhalt von reCAPTCHA laden, um das Formular abzuschicken. Bitte beachten Sie, dass dabei Daten mit Drittanbietern ausgetauscht werden.

Mehr InformationenSie sehen gerade einen Platzhalterinhalt von Facebook. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr Informationen